Air Handling Unit Refurbishment

Clean Room Manufacturing Facility & Labs. Warrior Close, Chandlers Ford.

With a total of 13 Air Handling Units serving a critical manufacturing process and science laboratories, all requiring modifications and refurbishments, including new HEPA filtration systems, fan upgrades, damper and coil remediation, new anti-leakage seals and BMS modifications delivered in a specific time frame, it takes real experience and meticulous planning.

Our client said; “We need to improve the reliability of the clean room environments, its critical to ensure our laboratories and manufacturing processes perform 24 hours a day”. “It is essential we have absolute control of the zones; air flows, IAQ and thermal loads. The products we produce, during manufacturing require specific air quality conditions.

“Unconditionally, the dependable solution, must reduce carbon emissions in line with the companies overall global Net Zero targets”

“There is only a 5-day window, over Christmas, during the shutdown period to carry out any improvements.”

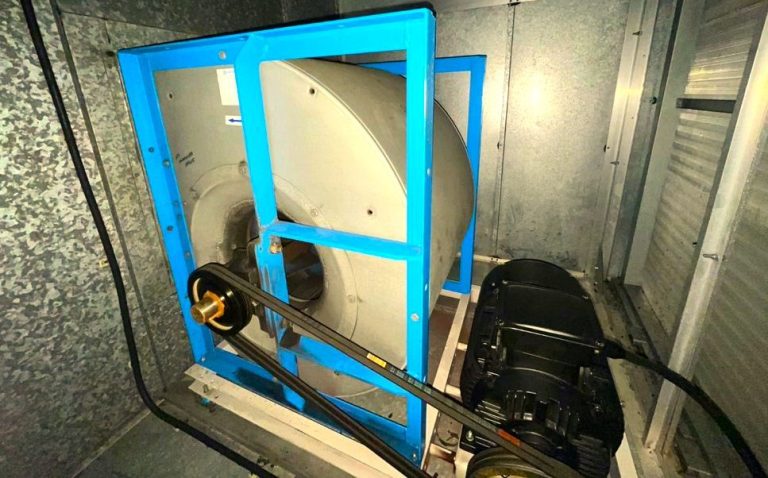

..Spoiler alert, we did it in 3 and a half days, whilst achieving a 26 tonne CO2e reduction per year! Read on to learn more.

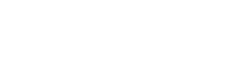

Fan Upgrade & AHU Remodelling

Prior to installation HALO HVAC validated all technical aspects of the system, designed structural modifications of the AHU, pre-wired all fans, along with Internal-rotor motor PM/EC technology that boasts an efficiency of IE6, exceeding motor energy efficiency classes set by both the International Electrotechnical Commission and European Efficiency.

The new maintenance-free fans were installed into each Air Handling Unit, for both supply and extract air streams. Along with predesigned and manufactured reinforced bulk heads, pre-welded bolts, and fan openings for a seamless installation.

This combines three solutions in a way that previously seemed almost impossible: Reliability with designed redundancy, outstanding system efficiency with high-power density for environmental control and 15–20-year extended life cycle for each AHU.

Before and After examples

Energy Saving Report

We conduct energy saving reports for all our delivered projects. No matter how small the saving may seem, a saving is a saving.

Typically, we deliver a 40% saving on every delivered project.

New high-efficiency particulate absorbing filtration system

– improved IAQ

Despite available technologies such as UVGI, ionic and ozone treatment, which use negative ions and ozone gas respectively to improve indoor air quality (IAQ). The likelihood of potential side-effects and down time is much lower with a suitably designed High Efficiency Particulate Absorbing filtration system, HEPA.

HALO HVAC designed and installed a total of 54 new HEPA filtration systems in accordance with EN1822:2019 and ISO 29463.

Furthermore, the filtration system has an in built anti-microbial coating to kill off the live bacteria and viruses trapped by the filter media. This filtration system offers an efficiency rating of 99.995%, which assures a very high level of protection against airborne transmission, and ultimately, offers optimum indoor air quality (IAQ) for our clients laboratories and clean rooms.

With HALO HVAC IOT it is possible to continuously remote monitor IAQ and accurately adjust based on live data to guarantee a consistent maintenance schedule.

All filter sections were thoroughly cleaned with specialist VOC free liquids, all filter sections were then treated with rust removal gels and VOC free rust treatments. New bag and panel filters were then installed throughout; The perfect air quality solution for clinical processes, such as science, laboratory and pharmaceutical.

Before and After examples

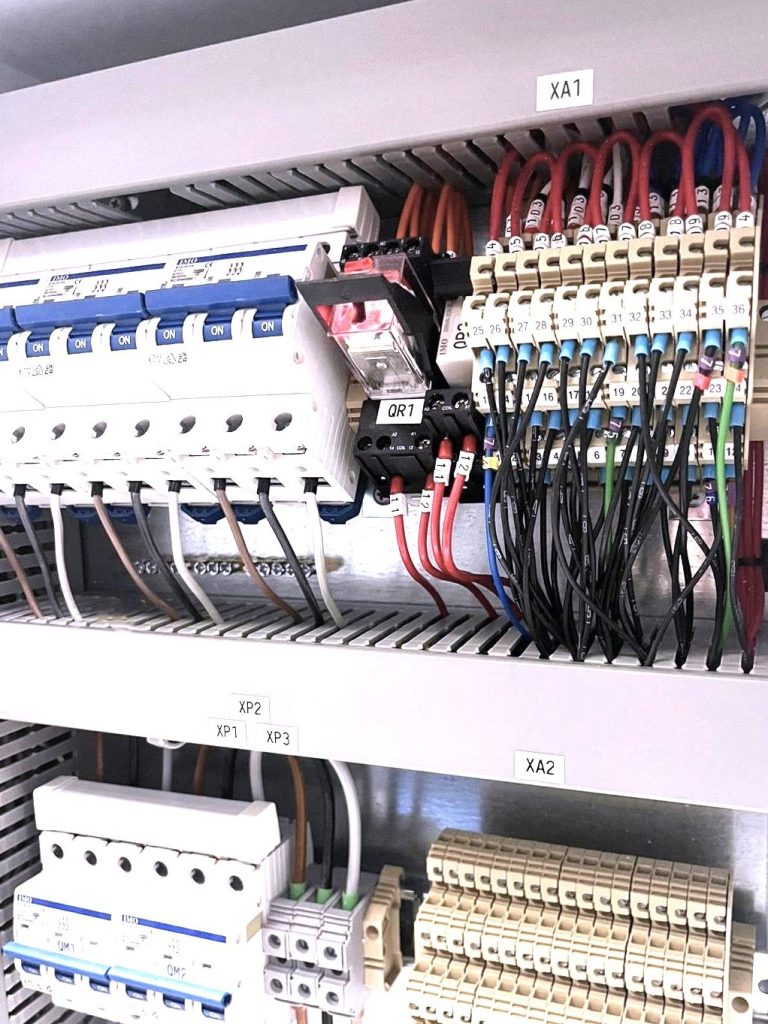

Upgrade of the BMS,

AHU communications, all electrical wiring, & panel modifications

The existing legacy controller information, AHU panel and SET files were uploaded with a backup taken, fully checked over for any errors prior to any modifications. The TREND software was updated and modified with new security features and speed control operation for the new high efficiency EC fan arrangement and associated sensors.

Enabling the future; HALO disconnected the existing cabling and removed legacy inverters. We then conducted the Installation of all new wiring for each fan output with new bespoke AHU breaker box, terminations, isolators and all new BMS interfaces and controls for each air handling unit.

The new BMS system was then fully validated and commissioned to enable the new fans to perform as per the air flow validations carried out by HALO HVAC using our own BSI and UKAS accredited BSRIA calibrated airflow and pressure reading equipment.

Each control panel was fitted with terminals to allow for future BMS integrations and MODBUS connectivity, should any modifications be required in the future, the enabling technology is already in place.

An Outstanding Project Delivery

With a total of 13 Air Handling Units serving a critical manufacturing process and science laboratories, all requiring modifications and refurbishments, including new HEPA filtration systems, fan upgrades, damper and coil remediation, new anti-leakage seals and BMS modifications delivered in a specific time frame, it takes real experience and meticulous planning.

When our client said, “we only have a 5-day window, over Christmas, during our shutdown period to carry out any improvements”. We knew we had to be comprehensive, engage with our supply chain, and Halo teams collectively to guarantee our client was back up and running at 100% production capacity with absolutely no delays or problems.

Many components were pre-designed and fabricated off site. Ensuring safety, compliance, and risk mitigation to support an impeccable project delivery. We pre-installed plantroom equipment protection prior to the shutdown and completed works that did not disrupt the ventilation systems at the earliest stages. This process enabled us to maximise on site time and guarantee the health and safety of everyone throughout the entirety of this project.

Prior to the works being undertaken, our team installed temporary plantroom services protection. The hoarding, walkways and hazard markers ensured we didn't impact the clients existing services through any error, whilst ensuring the absolute health and safety of our engineering team throughout the works. Photos as follows;

Watch the Case Study Video

Conformity & Compliance

HALO HVAC Ltd has passed industry leading conformity and compliance testing, verification, and inspection. Our accreditations highlight our technical competences, reliability, and integrity to provide confidence and trust to deliver our services.

We hold insurances for Contractors All Risk, Professional Indemnity, Employer Liability, Public and Product Liability, and Contract Works. We are members of Constructionline, Building Engineering Services Association (BESA), and The Contractors Health and Safety Schemes in Procurement (CHAS Advanced) including PAS91 and SSIP.

Call to request copies on 0207 117 2087 or email info@halohvac.co.uk

Clean Room & Labs, Chandlers Ford

13 Air Handling Units serving a critical manufacturing process and science laboratories, all requiring refurbishments, controls and BMS modifications, delivered in 5 days, whilst achieving 26t a year CO2e reduction.

5 Star Hotel, Knightsbridge, London

The belt-driven fans in the hotel's air handling units failed, causing no ventilation in critical areas; urgent reinstatement was essential for to ensure the Hotel was fully operational & compliant.

Kettering General Hospital

Bringing the Air Handling Unit in line with compliances such as HTM 03-01 whilst reclaiming lost heat through new ventilation strategies, enabling energy savings.

Food Manufacturer, Rugby

Ventilation is vital for food production, ensuring air quality and contamination prevention. Upgraded filtration and AHU refurbishment guaranteed compliance, reliability and effectiveness.

Offices. Gracechurch Street, London

With the building owners advertising for new leases a key objective was to ensure the indoor environment is comfortable and healthy. Over time, the existing AHUs became less efficient, leading to higher energy bills and reduced indoor air quality.

5 Star Hotel. Mayfair, London

This luxury hotel operates 24/7 therefore we had to deliver this project with zero disruption. We completed all works in 2 evenings whilst staging the works to allow for ventilation to continue during daytime hours.

Recent Projects;

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.