Advancing Compliance with HTM-03 Standards in Brighton

This extensive air handling unit refurbishment has not only improved the unit’s energy efficiency, reliability, and overall performance but has also aligned it more closely with HTM-03 compliance standards for healthcare. By integrating modern technology and optimizing system functionality, HALO HVAC ensures a healthier and more controlled environment, enhancing patient care and operational sustainability. The upgrade ensures the AHU refurb meets the rigorous demands of HTM-03 compliance, promoting better air quality, temperature control, and energy efficiency for improved healthcare facility operations.

Increased design air volume.

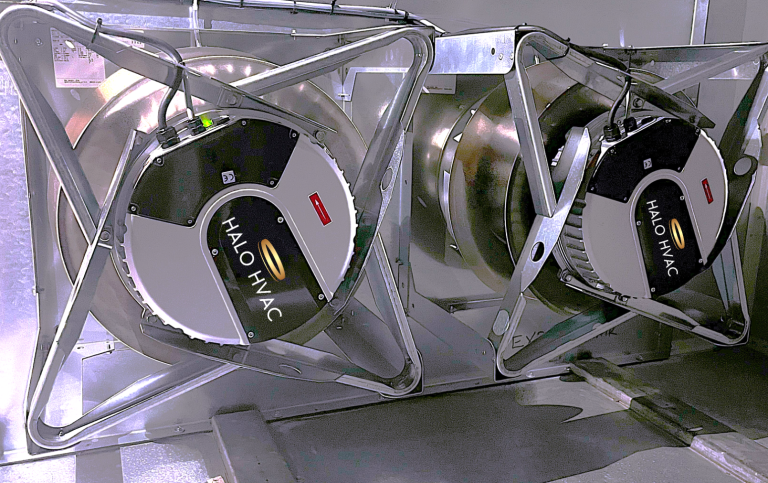

Upgraded belt driven fans to new run and standby EC plug fans with HALO HVAC 'quick clip' controls connections.

As part of the air handling unit (AHU) refurb and upgrade, HALO HVAC conducted a thorough assessment and successfully increased overall air volumes to enhance system performance and meet healthcare ventilation demands. To further improve energy efficiency, reliability, and bring the system closer to HTM 03-01 compliance, HALO HVAC upgraded the fans to direct-drive electronically commutated (EC) fans—the most efficient solution for healthcare environments.

According to HTM 03-01 Part A and Part B, fans account for approximately 40% of all electricity used in ventilation systems, making energy-efficient upgrades a key factor in reducing carbon emissions. European Regulation 1253/2014, under the Energy-related Products (ErP) directive, has introduced stringent efficiency requirements for fan power consumption, reinforcing the importance of adopting advanced, energy-saving solutions.

HTM 03-01 recommends EC fans over traditional belt-driven systems—now advised against in healthcare ventilation—due to their higher efficiency, lower energy consumption, and reduced maintenance needs. By eliminating energy losses associated with belts and pulleys, EC fans deliver smoother, more reliable operation, aligning with the latest regulatory standards.

For enhanced system resilience and capacity, HALO HVAC implemented a multi-fan configuration with integrated gravity dampers to prevent backflow and optimize airflow control. This setup ensures uninterrupted performance and greater flexibility in adapting to varying ventilation demands.

By integrating high-efficiency EC fans and increasing air volumes, HALO HVAC has significantly improved airflow management, reduced operational costs, and supported carbon reduction efforts, ensuring the AHU refurbishment meets the latest HTM 03-01 recommendations.

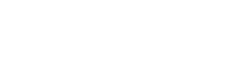

New epoxy coated plate heat exchanger with metal linkage face and bypass damper.

As part of our commitment to delivering high-performance HVAC solutions, HALO HVAC has installed a new epoxy-coated plate heat exchanger with a metal linkage face and bypass damper as part of an air handling unit refurbishment. This upgrade is essential for improving energy efficiency, air quality, and compliance with HTM-03 healthcare ventilation standards.

The epoxy coating protects the heat exchanger from moisture, chemicals, and airborne contaminants, ensuring long-term durability and reducing maintenance costs. By efficiently recovering heat from the exhaust air, the system reduces energy consumption while maintaining optimal indoor climate control.

The addition of a metal linkage face and bypass damper allows for precise airflow regulation, ensuring that temperature and humidity levels remain within safe limits. This feature also provides flexibility to bypass heat recovery when necessary, supporting infection control measures and preventing cross-contamination between fresh and exhaust air streams. With all associated motors installed out of airstream.

With this advanced AHU refurb, HALO HVAC enhances system performance, extends equipment lifespan, and helps healthcare facilities meet HTM-03 compliance, creating a safer and more efficient environment for patients and staff.

Powder coated ductwork and new cowl to increase the distance between the fresh air intake and exhaust air.

During this AHU refurbishment, HALO HVAC implemented key upgrades to enhance air quality and system efficiency. One significant improvement was the installation of powder-coated ductwork and a cowl to increase the separation distance between the fresh air intake and the exhaust air.

This strategic modification prevents cross-contamination, ensuring that exhausted air—potentially containing pollutants, airborne pathogens, or odors—does not re-enter the system. By drawing in cleaner air, the system supports a healthier indoor environment, particularly in sensitive settings such as healthcare facilities.

In addition to improving air quality, this upgrade also enhances energy efficiency by preventing the intake of warm or humid exhaust air, reducing strain on the HVAC system. The powder-coated ductwork provides an added layer of protection against corrosion, extending equipment lifespan and minimizing maintenance needs. By optimizing airflow and ensuring compliance with ventilation standards, HALO HVAC has reinforced the reliability and performance of the air handling system, contributing to a cleaner, safer, and more efficient indoor environment.

Installation of a new bare tube frost coil

Installing a new bare tube frost coil as part of an AHU refurbishment improves efficiency and ensures compliance with HTM-03 regulations for healthcare ventilation. This upgrade prevents frost buildup on downstream components, enhancing heat transfer, reducing energy consumption, and extending the AHU’s lifespan. The bare tube design minimizes pressure drop while optimizing thermal performance, ensuring consistent airflow and temperature control. The new coil was designed to suit the new increased air flow rate.

The AHU refurbishment process involves assessing the unit, selecting suitable materials (such as copper or stainless steel tubing), and ensuring system compatibility. After securely mounting the coil, integrating sensors, and connecting it to the heating system, performance tests verify airflow, temperature control, and frost protection. Proper commissioning ensures compliance with HTM-03 standards, system reliability, and long-term energy efficiency.

New copper/pre tinned cooling coil

with removable stainless steel moisture eliminators.

Installing a new copper or pre-tinned cooling coil with removable stainless steel moisture eliminators is a key upgrade in air handling unit refurbishment, improving efficiency and ensuring compliance with HTM-03 regulations. These high-performance coils enhance temperature transfer and reduce energy consumption, while the moisture eliminators prevent water carryover and microbial growth, maintaining clean air quality in healthcare settings.

The AHU refurbishment process involves assessing the unit, selecting the appropriate coil, and ensuring system compatibility. After removing the old coil, the new one is installed alongside easily removable moisture eliminators for simple maintenance. Sensors and controls are integrated to optimize cooling and humidity management, reducing strain on downstream components and extending system lifespan.

Post-installation, testing and commissioning verify system integrity through leak checks, airflow assessments, and moisture control optimization. Adjustments ensure compliance with HTM-03 standards, enhancing cooling performance, air quality, and long-term operational efficiency as part of a comprehensive air handling unit refurbishment strategy.

New Main Heating Coil

HALO HVAC installed a new main heating coil as part of this AHU refurbishment to bring the unit closer to HTM-03 compliance for a healthcare facility. The existing coil was replaced to improve energy efficiency, heat distribution, and air quality in line with HTM-03 regulations. HALO HVAC assessed the unit, selected a high-performance coil, and integrated it into the AHU, ensuring compatibility with existing components and optimizing system functionality.

The new coil was installed with a focus on reducing pressure drop and enhancing temperature control. Upgraded control systems were also integrated for precise operation. After installation, the system underwent testing to ensure it met the required standards for airflow, temperature, and safety. This refurbishment improved the AHU’s efficiency, reliability, and brought it closer to HTM-03 compliance, ensuring a healthier, more controlled environment for the healthcare facility.

All new powder coated and mellinex lined attenuators

The successful completion of the extensive AHU refurbishment has delivered significant improvements in energy efficiency, reliability, and overall performance. As part of this comprehensive air handling unit refurb and upgrade, powder-coated and Melinex-lined attenuators were installed, enhancing durability, corrosion resistance, and acoustic performance. These enhancements not only extend the lifespan of the AHU but also contribute to a quieter and more efficient hospital environment.

Additionally, the refurbishment brought the system closer to full compliance with HTM 03-01 standards, ensuring improved air quality, infection control, and operational efficiency. By implementing advanced filtration, optimized airflow management, and state-of-the-art components, the AHU refurbishment has provided the hospital with a robust, future-proof solution that meets the stringent demands of healthcare environments.

Low leakage stainless steel dampers including the addition of supply air and return air dampers.

As part of a recent air handling unit refurbishment, HALO HVAC installed low-leakage stainless steel dampers to (BS EN 1751 class 3), including new supply air and return air dampers, to enhance airflow control and ensure compliance with HTM-03 healthcare ventilation standards. These high-performance dampers play a crucial role in preventing cross-contamination by tightly regulating the separation between supply and return air. By minimizing air leakage, they help maintain the correct pressurization levels in critical healthcare environments such as operating rooms, isolation wards, and sterile areas. This ensures that clean air remains uncontaminated while effectively managing airflow distribution throughout the facility.

The stainless steel construction provides superior corrosion resistance, making the dampers highly durable in humid or demanding environments. Their low-leakage design improves energy efficiency by reducing air loss, allowing the AHU to operate at peak performance while lowering overall energy consumption.

By integrating these advanced dampers into the AHU refurbishment, HALO HVAC has enhanced system reliability, infection control, and operational efficiency, bringing the unit in line with HTM-03 compliance and ensuring a safer indoor environment for patients and staff.

New hinged access doors with portholes and comprehensive component labelling for improved identification and streamlined servicing.

As part of the air handling unit refurb and upgrade, new hinged access doors with integrated portholes were installed, allowing for easier inspection and maintenance while ensuring a secure and airtight seal.

Additionally, new component labeling was implemented throughout the system, providing clear identification for all parts and improving operational efficiency. These upgrades not only enhance accessibility, streamline servicing, and contribute to the overall longevity and performance of the AHU refurbishment but also bring the system closer to HTM 03-01 compliance, ensuring a more reliable, efficient, and user-friendly solution for hospital maintenance teams.

Within the internals of the AHU HALO HVAC applied corrosion treatment and stainless steel plate work.

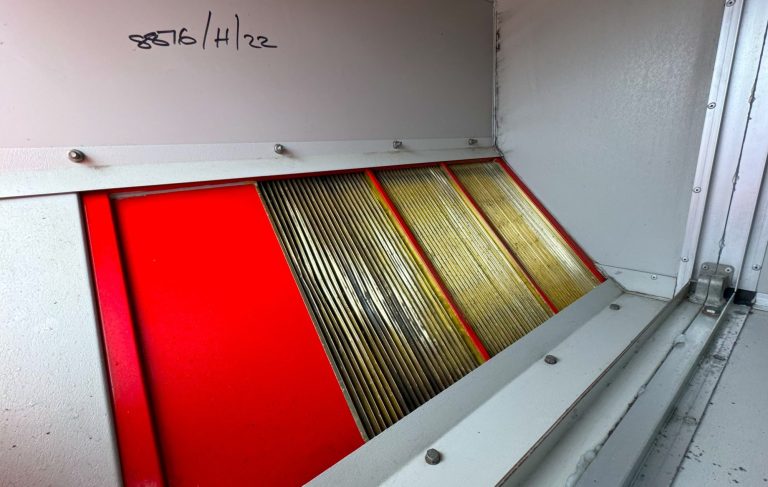

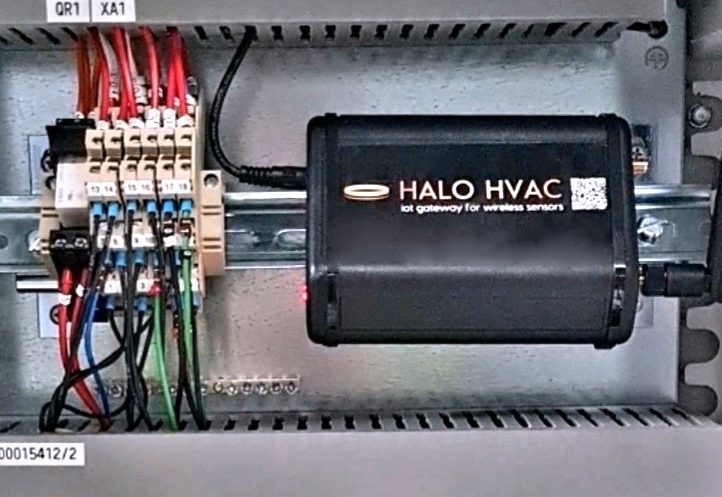

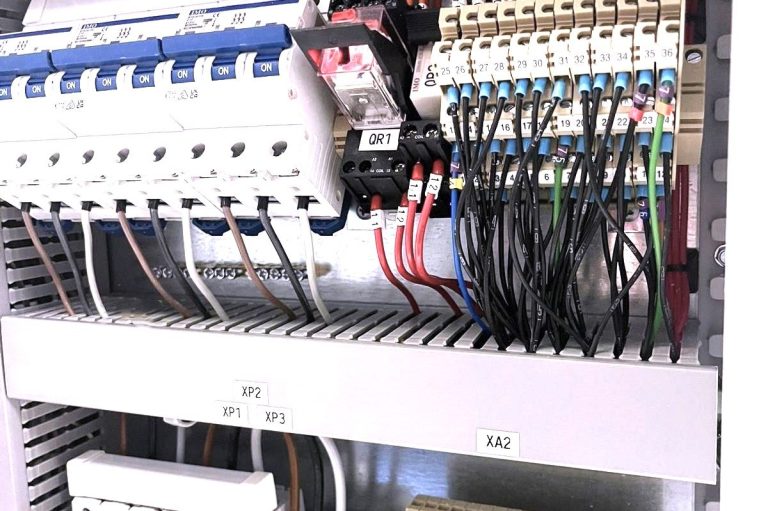

Enhanced Electrical & Control System Integration for Improved Compliance & Efficiency

As part of the air handling unit (AHU) refurbishment to bring the system closer to HTM 03-01 compliance, HALO HVAC has undertaken a comprehensive electrical and controls upgrade, ensuring seamless integration, enhanced safety, and optimized performance.

Key Electrical System Upgrades:

- New isolators were installed to provide safe and secure power disconnection for maintenance, reducing downtime and ensuring compliance with electrical safety regulations.

- Upgraded junction box to streamline electrical connections, enhancing durability and accessibility for maintenance teams.

- New wiring from the internal bulkhead lighting to a single external switch, simplifying operation and ensuring safer, more efficient control of internal LED illumination to IP55 rating.

To further enhance efficiency and compliance, all new controls were fully integrated into the hospital’s existing Building Management System (BMS). This seamless integration allows for:

- Centralized monitoring and control, enabling facility managers to track AHU performance in real-time.

- Automated energy optimization, adjusting airflow, temperature, and fan speeds based on demand to reduce energy consumption and operational costs.

- Remote fault detection and diagnostics, minimizing downtime and allowing for proactive maintenance before issues arise.

- Improved compliance with HTM 03-01, ensuring the AHU operates within the strict guidelines set for healthcare ventilation systems.

By modernizing the electrical infrastructure and seamlessly integrating the AHU controls into the existing BMS, HALO HVAC has significantly improved system resilience, energy efficiency, and long-term reliability, ensuring a smarter, more future-proof solution for the hospital’s critical ventilation needs.

Commitment

Our commitment to comprehensive and customer-focused solutions lies at the core of everything we do. We understand that each client has unique needs and priorities, which is why we prioritize understanding those needs before crafting our solutions.

Approach

Our holistic approach to AHU refurbishment encompasses not only the technical aspects but also factors such as energy efficiency, sustainability goals, and overall system longevity. By considering these factors, we ensure that our refurbishment projects not only meet but exceed our clients' expectations.

Innovation

At HALO HVAC, we use innovative technologies to boost AHU system efficiency. Through smart controls and energy-efficient components, we aim to optimize energy usage, cut operating costs, and support clients in achieving net-zero ambitions.

Sustainability

Our sustainable solutions and commitment to customer value, coupled with contributions to broader sustainability goals, distinguish us in the industry. Choose HALO HVAC for AHU refurbishment to receive tailored solutions for your needs and CO2e reduction goals.

AHU Refurbishment Services Overview;

EC Fan Upgrade

Switching to EC fan arrays enhances efficiency, resulting in significant energy and CO2 savings. These fans also provide redundancy in multi-fan setups and require easy maintenance without traditional components like belts and pulleys.

Filters & Air Treatment

Upgrading your filters and housings in line with ISO 16890 can significantly improve IAQ, system pressure drop, and energy consumption, reflecting a commitment to advanced technologies and overall system efficiency.

Coils

Replacing worn or damaged coils is essential for restoring optimal performance. Over time, changes in set point parameters may necessitate the installation of new coils that are heat pump ready.

Dampers

Replacing or repairing dampers and actuators in damaged areas ensures the restoration of airflow set-points while minimizing pressure drop.

Controls & BMS Mods

HALO HVAC ensure energy efficiency and future adaptability. With seamless integration into Building Management Systems (BMS) our HVAC services provide centralized control guaranteeing a smart, sustainable solution for evolving control needs.

Mechanical & Electrical

HALO HVAC provides a comprehensive suite of services as part of an AHU upgrade, specializing in mechanical and electrical installations for both commercial and industrial settings.

Conformity & Compliance

HALO HVAC Ltd has passed industry leading conformity and compliance testing, verification, and inspection. Our accreditations highlight our technical competences, reliability, and integrity to provide confidence and trust to deliver our services.

We hold insurances for Contractors All Risk, Professional Indemnity, Employer Liability, Public and Product Liability, and Contract Works. We are members of Constructionline, Building Engineering Services Association (BESA), and The Contractors Health and Safety Schemes in Procurement (CHAS Advanced) including PAS91 and SSIP. HALO HVAC is SafeContractor certified.

We are an Upper-Tier Waste Carrier, Broker and Dealer with the Environment Agency, Department for Environment Food & Rural Affairs licence number CBDU555299

Call to request copies on 0207 117 2087 or email info@halohvac.co.uk

Healthcare

There is no restriction to the applications that are suitable for AHU refurbishment.

HALO HVAC provides AHU refurbishment across the UK, in almost every sector 24/7.

Pharmaceutical

Data Centre

Commercial Office

Food Industry

Industrial

Leisure

Life Science

Education

Book your free

AHU survey, today.

Fill in the form and we'll do the rest.

Or call us on 0207 117 2087

Latest News

HVR Awards

We are honoured to create a partnership with Heating Ventilation Review for the 2024 HVR Awards!

NEW - White Paper :

Learn how Integrating IoT with AHU refurbishment enables sustainable HVAC energy upgrades.

Case Study : Cutting carbon by removing on-site gas-fired boilers and remodelling the AHU's by adopting new DX heat pump technology.

Case Study : 13 AHU's serving a critical manufacturing process and science labs, upgraded and delivered in less than 5 days.

Case Study : Ministry of Defence (MOD) Decarbonisation through

AHU Refurbishment & New Cutting-Edge Air Source Heat Pumps.

Nominated for Two Awards :

Thrilled to announce we have been shortlisted for both, Building A Safer Future Award & Building Services Project of The Year !!

Case Study: This luxury 5* Mayfair hotel operates 24/7 - Therefore, we delivered this project with zero disruption to guests and services.

NEW: CPD and Training sessions by HALO HVAC experts - certified content for HVAC industry professionals.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.